Online real-time certification and digital mapping of the value chain

Online real-time certification and digital mapping of the value chain

Industry 4.0 – the term is currently omnipresent. It generally refers to the comprehensive digitalisation of industrial production. However, many decision-makers still find it difficult to grasp concrete approaches to realising benefits from this.

Digitisation has considerable implications for companies. In automated processes along the value chain and in the entire product life cycle, large amounts of data on production and sales can be collected and analysed. This enables innovation and has the potential to increase competitiveness on a global level.

Industry 4.0 is usually about connecting people, machines and processes in a dynamic system. Application scenarios can delay groundbreaking decisions on digitization, especially in the more traditional steel and metal industry, due to potentially dubious feasibility and high costs. A concrete digital approach to the realization of significant optimization potentials in the supply chain should open up new growth opportunities and competitive advantages for manufacturers.

The steel industry in Germany is currently under great competitive pressure. Cheap steel from the Far East, a decline in demand from the automotive and mechanical engineering industries, increasingly strict climate regulations and other factors such as the corona crisis are shaping international competition. Future-oriented strategies, such as orientation towards markets with high growth potential (outside the EU), closer customer ties, faster product development, concentration on higher-margin business and tailor-made products appear necessary and sensible. An expansion of core competencies in conjunction with strategic initiatives is fundamental. In terms of competitiveness and future viability, strategy and digitization initiatives should go hand in hand.

Even small-scale digitization measures represent a first step towards Industry 4.0 and can have measurable effects – especially since the production site remains at the heart of Industry 4.0. Efficiency gains and faster response times will significantly increase the competitiveness and future viability of German steelworks and processors – especially for high-quality, tailor-made products that can be offered at the price of a mass product. Although this digitalization approach is focused on internal processes, it is very relevant with regard to the export business.

When exporting first-class products, German manufacturers have to deal with the cost factor of plagiarism and forgery of certificates. Conventional, paper-based certificates can be used or imitated to sell counterfeit products. Expensive products with high quality as a unique selling point invite counterfeiting of certificates by unfair market participants. Experts estimate the associated damage in the form of lost sales to the industry in Germany at billions of euros per year. Intelligent, online-based solutions can solve this problem and additionally make data usable within the framework of Industry 4.0.

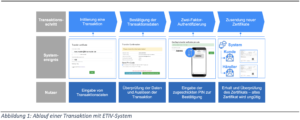

Such a solution is offered by the innovative and highly specialized ETIV-System GmbH from Cologne. As an end-to-end real-time verification system, the platform increases counterfeit protection for the industry. It offers manufacturers a solution tailored to their needs and does not require any additional IT effort on their part. The manufacturer uploads a PDF file of the certificate or mill test report issued in-house via the secure platform and the end-to-end verification is performed by ETIV-System GmbH. The system automatically reads important information (e.g. weight, dimensions, product characteristics and certificate history) from the document and generates a new, unforgeable digital certificate.

This e-certificate is based on the old certificate, has an additional QR code and can be downloaded as a PDF file. The QR code can be read with any smartphone without the need for additional software and the certificate can be verified directly. For each transaction, a new certificate is automatically generated for the amount of steel sold and sent digitally by e-mail to the parties involved. The old certificate is immediately invalidated and a new certificate is created for the remaining quantity of the product. Each transaction for products with this type of certificate is carried out according to this procedure. Thus, the total amount of product contained in the certificates available on the market is exactly the same as the amount that originally left the factory.

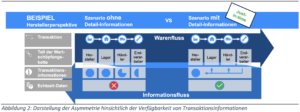

In addition to the many advantages of high counterfeit protection, a major benefit of this system is the digital representation of the entire horizontal value-added chain from the manufacturer to the warehouse to the end user. This is because valid and transparent transaction data from the entire supply chain is captured by digital real-time logging and certification, enabling the manufacturer to evaluate the product cut and processing times right through to its use by the end processor (see also Figure 2). This data enables manufacturers to realize an optimization of the entire supply chain (e.g. for inventory, market forecast, delivery speed). The manufacturer benefits from the ready-to-use solution from ETIV-System without having to have his own IT effort and can draw on the know-how of the experts. Low investment costs and risks make the offer very attractive for manufacturers. The use of ETIV-System opens up growth opportunities and competitive advantages for manufacturers as well as a more dynamic, flexible and efficient production through the flow of information along the horizontal value chain.

Author: Dr. Hossein Askari. Managing Director ETIV-System GmbH